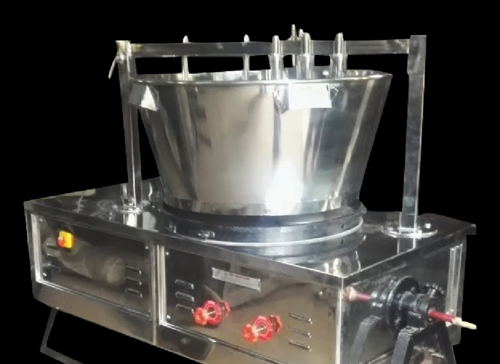

Srikhand Making Machine

Price 50000 INR/ Unit

Srikhand Making Machine Specification

- Operating Temperature

- Up to 50C

- Automation Grade

- Automatic

- Heating Method

- No direct heating

- Frequency

- 50/60 Hz

- Phase

- Three Phase

- Noise Level

- Low

- Speed Mode

- Variable

- Machine Type

- Automatic Srikhand Maker

- Function Type

- Batch Type

- Power Source

- Electric

- Feeding System

- Automatic

- Product Type

- Food Processing Machinery

- General Use

- Manufacturing of Srikhand and Dairy Products

- Material

- Stainless Steel

- Type

- Srikhand Making Machine

- Capacity

- 100 to 500 kg/hr

- Weight (kg)

- 850 kg

- Product Shape

- Rectangular

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Standing

- Dimension (L*W*H)

- 1800 x 900 x 1900 mm

- Raw Material

- Stainless Steel (Food Grade)

- Color

- Silver

Srikhand Making Machine Trade Information

- Minimum Order Quantity

- 10000 Units

- Supply Ability

- 100000000 Units Per Week

- Delivery Time

- 2 Hours

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Stretch packing

- Certifications

- ISO 2004

About Srikhand Making Machine

Catering to the wide requirements of food industries, we are reckoned for manufacturing and exporting Srikhand Muska Machine. These machines are widely used of preparing delicious srikhand in bulk quantity. Takes no time time to prepare this sweet, these machines are integrated with highly functional and advanced components, sourced from the reputed market vendors. We offer this Srikhand Muska Machine to our clients in different models at competitive prices.

Features

- Food grade construction

- Robust design

- Minimal maintenance

Further Details

We are experts in manufacturing and supply of sweet making machines. This sweet making machine is used to prepare the famous and delectable "Mysore Pak" and "Milk Khova" sweets. The best aspect of this machine is it is economical in terms of money and consumption of fuel. This low maintenance sweet processing piece of equipment is fabricated out of MS Body with stainless steel vassals. M.S. Bottom Plate stainless steel body with stainless vassal. M.S. Bottom Plate is also available fully stainless steel.

Advanced Engineering for Consistent Results

This Srikhand Making Machine features a fully automatic, PLC-controlled system that streamlines operation, allowing consistent product quality and minimal manual intervention. The variable speed and automatic feeding system support diverse production needs, maximizing efficiency and output.

Optimal Hygiene and Safety with Food-Grade Construction

Manufactured from high-grade stainless steel, the machine ensures superior hygiene standards vital in dairy production. Its robust build and enclosed design prevent contamination and support easy cleaning between batches.

Versatile Production and Ease of Installation

With a capacity spanning 100 to 500 kg/hr and process adaptability, the unit fulfills the needs of small and large dairies alike. Its free-standing design simplifies installation, requiring only a three-phase electric connection, making it a convenient choice for exporters, manufacturers, and suppliers.

FAQs of Srikhand Making Machine:

Q: How does the Automatic Srikhand Making Machine operate?

A: The machine operates using a PLC (Programmable Logic Controller) system, ensuring automatic mixing, feeding, and processing of dairy products. Once the ingredients are loaded, the system handles the mixing and batching without manual intervention.Q: What benefits does computerized control offer in this machine?

A: Computerized control guarantees accurate and repeatable operations, lower error rates, and easy adjustments to process parameters, enabling manufacturers to achieve consistent Srikhand quality and reduce production downtime.Q: When should this machine be used in the dairy production process?

A: This equipment is designed for use after milk has been processed into curd. It handles the mixing, flavoring, and batching steps required to turn strained curd into finished Srikhand, streamlining a key stage of dairy production.Q: Where can this machine be installed?

A: Its free-standing structure and compact dimensions allow installation in commercial dairy plants, food processing factories, and large-scale kitchens. Only a suitable floor area and three-phase electric connection are required.Q: What is the process of making Srikhand in this machine?

A: The process involves loading the pre-strained curd and other ingredients into the machine, setting the desired parameters via the control panel, and letting the automated system perform mixing and batching. The product is processed in batches with no direct heating involved.Q: What types of dairy products apart from Srikhand can be made?

A: While optimized for Srikhand, the machine can be adapted to produce similar dairy-based desserts or products that require batch mixing, enhancing its versatility for manufacturers.Q: What are the key usage and maintenance steps for this equipment?

A: Regular cleaning after each batch and scheduled maintenance as per the manufacturers guidelines ensure optimal performance and longevity. The stainless steel build supports easy sanitation and resistance to wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sweets Making Machines Category

Ross Gulla Gulab Jamun Making Machine

Price 200000 INR / Unit

Minimum Order Quantity : 10000 Pieces

General Use : Commercial Sweets Production

Material : Other, Stainless Steel (SS304/SS316)

Computerized : No

Automatic : Yes

Chikki Making Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial

Material : Stainless Steel

Computerized : No

Automatic : No

Mysorepak Making Machine

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Industrial

Material : Stainless Steel

Computerized : No

Automatic : No

Send Inquiry

Send Inquiry