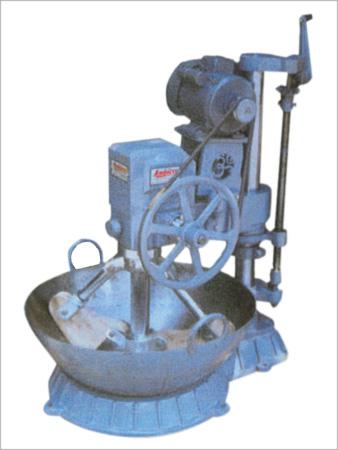

Multi Machine Food Processing machine

Price 35000 INR/ Unit

Multi Machine Food Processing machine Specification

- Operating Temperature

- 050C

- Power Source

- Electric

- Features

- Corrosion Resistant, Overload Protection, Low Power Consumption, Robust Construction

- Automation Grade

- Automatic

- Frequency

- 50/60 Hz

- Phase

- Single/Three Phase

- Machine Type

- Modular

- Feeding System

- Manual Hopper/Automatic Conveyor

- Noise Level

- Below 80 dB

- Product Type

- Multi Machine Food Processing Machine

- General Use

- Food Preparation (Mixing, Grinding, Slicing, Cutting, Chopping, Shredding)

- Material

- Stainless Steel, Food Grade Plastic

- Type

- Commercial Food Processing Machine

- Weight (kg)

- 420 kg

- Product Shape

- Rectangular Cabinet with Multiple Process Attachments

- Computerized

- No

- Automatic

- Yes

- Control System

- Digital Touch Control Panel

- Installation Type

- Standalone, Floor Mounted

- Power

- 3.0 kW

- Dimension (L*W*H)

- 1850 x 980 x 1600 mm

- Raw Material

- Vegetables, Fruits, Meat, Grains

- Color

- Stainless Steel Finish

Multi Machine Food Processing machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- Unit

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- Stretch packing

- Certifications

- ISO 2004

About Multi Machine Food Processing machine

We are well known as one of the prominent manufacturers and exporters of Multi Machine Food Processing Machine. These machines are highly advanced in their operation and thus widely recommended in the food industries. Specially engineered and manufactured for the purpose of roasting and frying onion, coconut and coriander seeds, these processing machines can also easily remove the moisture from the products thereby increasing their shelf life. Depending upon the clients' diverse requirements in the industry, we make available this Multi Machine Food Processing Machine in different specifications and capacities.

Features

- Multi- purpose machine

- Robust construction

- Easy installation and maintenance

Multi Machine

It is a rapid roasting machine used for frying / roasting onion, coriander, coconut and for removing moisture & increasing shelf life of powder, chemicals, spices. The blender consists of outer & inner spiral ribbons supported on a centrally mounted longitudinal axis. When the agitator rotates, the material is carried radically around the inside of the blender. The outer & inner ribbon moves the material in opposite directions.

Versatile Food Processing

This modular machine is equipped with a rectangular cabinet layout and interchangeable process attachments, allowing users to seamlessly perform mixing, grinding, cutting, chopping, shredding, and more. Its adaptability makes it ideal for handling diverse food types such as vegetables, fruits, grains, and meat, maximizing efficiency in commercial kitchens and food production lines.

Smart Digital Controls

Navigating the Multi Machine Food Processing unit is effortless thanks to its digital touch control panel. Users can set processing cycles, monitor operational status, and adjust settings for different applications at the touch of a finger. The system is engineered for reliability, offering both manual and automatic feeding options to accommodate different workflow requirements.

Durable and Energy-Efficient Design

Constructed from high-grade stainless steel and robust food-safe plastic, this floor-mounted machine boasts corrosion resistance and overload protection. Its 3.0 kW energy-efficient operation, combined with low noise output and support for single or three-phase power, makes it suitable for continual use in demanding environments. The straightforward installation ensures minimum disruption to existing kitchen layouts.

FAQs of Multi Machine Food Processing machine:

Q: How do I operate the Multi Machine Food Processing machines control system?

A: The machine features a digital touch control panel that allows you to easily select and adjust processing cycles. Simply choose the desired functionsuch as mixing, grinding, or slicingset the relevant parameters, and commence operation. The panel provides clear prompts for smooth user interaction.Q: What raw materials can this processing machine handle effectively?

A: This machine is designed for versatility and can process vegetables, fruits, grains, and various types of meat. The multiple process attachments ensure effective preparation of a wide range of raw materials for different commercial culinary needs.Q: When is this machine most beneficial for commercial kitchens or food industries?

A: The machine proves most beneficial in environments requiring high-volume, continuous food processing tasks. Its ability to perform various functions with minimal supervision makes it ideal for restaurants, canteens, food manufacturers, and large catering operations.Q: Where should the machine be installed for optimal use?

A: The machine is a floor-mounted, standalone unit, best placed in a spacious section of your commercial kitchen or processing facility with access to a suitable electric power source (single or three phase). Ensure sufficient clearance around the machine for safe operation and maintenance.Q: What steps are involved in the food processing operation?

A: Start by loading raw materials via the manual hopper or automatic conveyor. Select the desired processing function and configure settings on the touch panel. The automatic system then completes the selected operationmixing, grinding, chopping, or shreddingwith minimal supervision.Q: How does the feeding system enhance the machines usage?

A: The machine offers both a manual hopper and automatic conveyor for feeding raw materials, giving operators flexibility and reducing manual effort during high-volume processing. This dual feeding system improves throughput and accommodates various production setups.Q: What are the main benefits of using this commercial food processing machine?

A: Key benefits include robust construction, corrosion resistance, overload protection, low power consumption, and quiet operation. The modular design, quick installation, and versatility across food types significantly enhance productivity and ensure reliability in busy commercial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Machine Category

Sandwich Griller

Price 20000 INR / Piece

Minimum Order Quantity : 10000 Pieces

Feeding System : Manual Loading

Type : Other, Contact Grill / Panini Press

Color : Other, Stainless Steel/Silver & Black

Voltage : 220240 V

Lassi Maker

Price 20000 INR / Unit

Minimum Order Quantity : 30000 Units

Feeding System : Manual

Type : Other, Beverage Mixer

Color : Other, Silver

Voltage : 220 V

Send Inquiry

Send Inquiry