Double Arm Blender

Price 1 INR/ Piece

Double Arm Blender Specification

- Operating Temperature

- Ambient to 80C

- Function Type

- Mixing Other

- Frequency

- 50 Hz

- Machine Type

- Batch Type

- Power Source

- Electric

- Heating Method

- Optional (Jacketed Heating)

- Phase

- Single or three Phase

- Features

- Robust Design, High Mixing Efficiency, Low Maintenance

- Speed Mode

- Variable

- Noise Level

- Low

- Feeding System

- Manual/Automatic

- Automation Grade

- Automatic

- Product Type

- Industrial Blender

- General Use

- Industrial Mixing / Blending

- Material

- Other

- Type

- Double Arm, Food Dryer, Food Processors, Snacks Extruder

- Capacity

- 50 Liters to 1000 Liters

- Product Shape

- Other

- Computerized

- No

- Automatic

- Yes

- Control System

- Other

- Installation Type

- Other

- Raw Material

- Other

- Feature

- Easy to Clean, Compact Design, Heavy Duty Construction, High Efficiency, Compact Structure, ECO Friendly, Low Noice, Lower Energy Consumption

- Color

- Other

- Service Support

- Onsite installation and training

- Discharge Type

- Bottom Discharge Valve

- Mixing Arms Material

- Stainless Steel 304 or 316

- Gearbox Type

- Heavy Duty Helical

- Application

- Pharmaceuticals, Food, Chemicals, Plastics, Ceramics

- Drive System

- Electric Motor with Gear Reduction

- Customizable

- Yes, as per requirement

- Surface Finish

- Paint Coated or Mirror Polished (for SS)

- Safety Features

- Emergency Stop, Overload Protection

Double Arm Blender Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Pieces Per Day

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Main Domestic Market

- South India

About Double Arm Blender

Competitive Edge for Industrial Mixing

Double Arm Blender stands out with its robust design and rare blend of heavy-duty construction, forming a formidable presence in pharmaceuticals, food, chemicals, ceramics, and plastics industries. The adaptable system is perfectly suited for batch mixing and blending plants, ensuring high efficiency for both powder and granule raw materials. With plant applications spanning diverse industrial sectors, its compact profile and high-speed variable modes ensure minimal footprint and easy integration into existing workflow.

Certifications, Packaging, and Reliable Delivery

Our Double Arm Blender is certified for quality and safety, assuring reliable performance. Each unit is packaged with utmost care to prevent damage during transit and to ensure pristine arrival. Flexible supply ability supports large-scale production, pairing strong logistics with prompt delivery schedules. Exporting, manufacturing, and supplying from India, we prioritize smooth delivery and onsite installation, helping clients experience streamlined operations from the moment of arrival.

FAQ's of Double Arm Blender:

Q: How does the Double Arm Blender enhance industrial mixing processes?

A: The Double Arm Blender utilizes a heavy-duty helical gearbox and variable speed controls to achieve consistent, high-efficiency mixing for powders and granules, producing uniform blends suitable for industrial applications.Q: What safety features are included in the Double Arm Blender?

A: Safety is prioritized with integrated emergency stop controls, overload protection, and secure bottom discharge valves, making operations stable and reducing potential hazards during industrial use.Q: When can customers expect delivery and installation support?

A: Upon order confirmation, our logistics team organizes timely delivery. We provide onsite installation and training right after arrival, ensuring clients can immediately operate the equipment.Q: Where is the Double Arm Blender most commonly used?

A: This blender is ideally deployed in pharmaceutical, food, chemical processing, ceramic, and plastics manufacturing plants, integrating efficiently into existing industrial setups.Q: What are the customization options available for this product?

A: Clients can request tailored specifications for material grade, surface finish, capacity, and additional features to cater to unique operational requirements, ensuring optimal utility for each application.Q: How easy is it to maintain and clean the Double Arm Blender?

A: Designed for easy cleaning and minimal maintenance, the machine's compact build and choice of surface finish help facilitate swift sanitation, reducing downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Machinery Category

Tray Drayer

Price 1 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Roasting, Cooking

Automatic : Other

Material : Stainless Steel

Computerized : No

Ribbon Blender

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Mixing and Blending of Dry Powders, Granules

Automatic : Yes

Material : Other, Mild Steel / Stainless Steel

Computerized : No

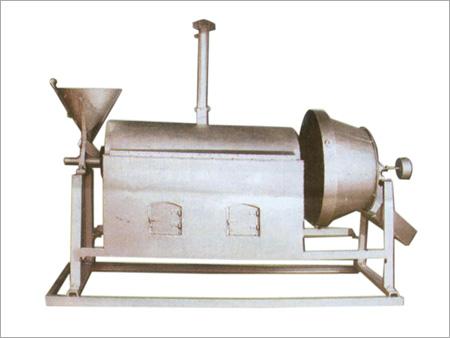

Mini Roaster Machine

Price 25000 INR

Minimum Order Quantity : 1 Unit

General Use : Roasting Coffee, Seeds, Spices, Nuts

Automatic : Yes

Material : Stainless Steel

Computerized : No

Hammer Mill

Price 56.0 INR / Piece

Minimum Order Quantity : 1 Piece

General Use : Restaurant

Automatic : No

Material : Other, Steel

Computerized : No

Send Inquiry

Send Inquiry