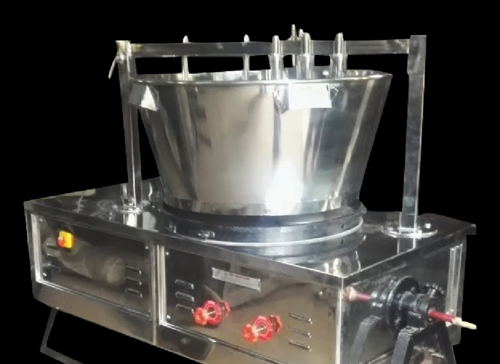

Ross Gulla Gulab Jamun Making Machine

Price 200000 INR/ Unit

MOQ : 10000 Pieces

Ross Gulla Gulab Jamun Making Machine Specification

- Heating Method

- No direct heating (for dough only)

- Frequency

- 50-60 Hz

- Phase

- Single Phase

- Feeding System

- Continuous Automatic Feed

- Machine Type

- Ras Gulla/Gulab Jamun Automatic Maker

- Power Source

- Electric

- Noise Level

- Low

- Speed Mode

- Multi Speed

- Function Type

- Dough Forming, Ball Shaping

- Automation Grade

- Automatic

- Operating Temperature

- Ambient to 45C

- Features

- Corrosion Resistant, Low Maintenance, Precise Shaping

- Product Type

- Sweet Making Machine

- General Use

- Commercial Sweets Production

- Material

- Stainless Steel (SS304/SS316)

- Type

- Food Processing Machinery

- Capacity

- 12000-15000 pieces/hr

- Weight (kg)

- Approx. 110-150 kg

- Product Shape

- Round, Spherical (for Rasgulla, Gulab Jamun, etc.)

- Computerized

- No

- Automatic

- Yes

- Control System

- Push Button/Manual

- Installation Type

- Free Standing

- Voltage

- 220-240 V

- Power

- 1-2 HP

- Dimension (L*W*H)

- Approx. 750 x 500 x 1100 mm

- Raw Material

- Khoa, Chhena, Flour Mixture

- Feature

- High Efficiency, Easy to Operate, Stainless Steel Body

- Color

- Silver

Ross Gulla Gulab Jamun Making Machine Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 7 Days

About Ross Gulla Gulab Jamun Making Machine

We are leading supplier ofRoss Gulla Gulab Jamun Making Machine. It is multi-purpose machine used Cutting Rounding, Rolling Machine. It is useful for making Ross Gulla, Gulab jamun, Kaju Roll, Peda Making Purpose, also useful for Dough Ball Cutting Purpose, made of Food Grade Stainless Steel, High-Quality Finishing, very high-speed production capacity, maintenance free, easy to operate and easy to cleaning system, speed controlling panel board,Boost Production Efficiency

Enhance your sweets manufacturing process with this fully automatic Gulab Jamun making machine, capable of shaping and forming up to 15,000 products per hour. Designed for high-volume operations, it optimizes workflow and ensures uniform product size and quality across each batch.

Effortless Operation and Maintenance

Operating the Ross Gulla Gulab Jamun Making Machine is straightforward, requiring only one person thanks to its push button/manual system. Cleaning is also hassle-free, as the machine is engineered for easy disassembly, minimizing downtime and allowing for quick transitions between production runs.

Premium Build for Longevity

Manufactured using food-grade stainless steel with a sleek mirror finish, this machine offers both visual appeal and lasting durability. Corrosion resistance and robust safety features safeguard both the operator and the investment, supporting consistent, safe, and hygienic performance in commercial settings.

FAQs of Ross Gulla Gulab Jamun Making Machine:

Q: How does the Ross Gulla Gulab Jamun Making Machine enhance production efficiency?

A: This machine automates the ball shaping process, delivering a high output of 12,000 to 15,000 pieces per hour. Its continuous automatic feed and multi-speed options ensure consistent, rapid production, significantly reducing manual labor and improving operational speed for commercial environments.Q: What types of sweets can I produce with this machine?

A: The machine is designed to produce round and spherical sweets such as gulab jamun, rasgulla, and laddoo. Its adjustable ball size feature allows for versatility in producing different product sizes as per your requirement.Q: How is cleaning and maintenance managed for this machine?

A: Cleaning is straightforward due to the easy-to-disassemble construction. The stainless steel body resists corrosion and ensures all food contact parts are hygienic. Regular maintenance involves simple checks, making the machine ideal for frequent use without extensive downtime.Q: Where can the machine be used most effectively?

A: It is suitable for use in industrial kitchens, sweet shops, and food processing unitsessentially any setting that demands large-scale, consistent sweet production. Its free-standing design and caster wheels facilitate placement and movement within various commercial spaces.Q: What are the safety features incorporated in the machine?

A: The machine prioritizes operator safety with an emergency stop button and protective safety guards. These features minimize risk during operation and maintenance, ensuring a safe workplace without compromising efficiency.Q: What is the process for operating the machine?

A: Operation is simple: load the prepared dough mixture (such as khoa, chhena, or flour mixture) into the hopper, select the desired ball size using the adjustable settings, and use the push button or manual controls to start. The machine automatically shapes, forms, and dispenses the sweets ready for further processing.Q: What benefits can commercial producers expect from using this machine?

A: Users benefit from high production output, consistent product quality, low noise, easy mobility, and reduced labor costs. Its robust stainless steel construction and easy cleaning system also promote hygiene and longevity, ultimately boosting productivity and profitability for commercial sweet manufacturers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Sweets Making Machines Category

Srikhand Making Machine

Price 50000 INR / Unit

Minimum Order Quantity : 10000 Units

Product Type : Food Processing Machinery

General Use : Manufacturing of Srikhand and Dairy Products

Material : Stainless Steel

Computerized : Yes

Chikki Making Machine

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Chikki Making Machine

General Use : Industrial

Material : Stainless Steel

Computerized : No

Mysorepak Making Machine

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Mysorepak Making Machine

General Use : Industrial

Material : Stainless Steel

Computerized : No

Send Inquiry

Send Inquiry